| Table of Contents |

|---|

一、Picking Rule

1、the function of picking rule

According to the set of picking rules, create the picking list automatically.

2、How to set picking rule

OWMS——>Picking——>Picking Rule,add

...

Picking type and warehouse are required

3、Notice of picking up rules

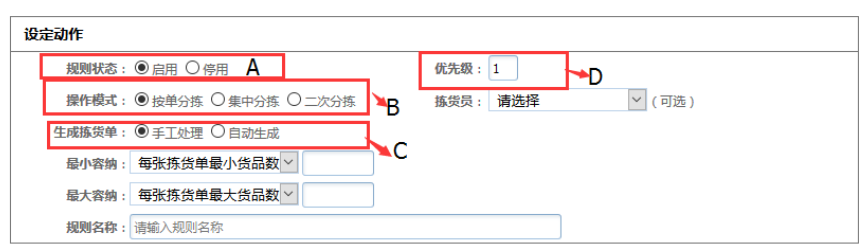

A:active the rule;

B:picking type:According to the order type:single order,multi-order

...

D:priority:run the larger number first

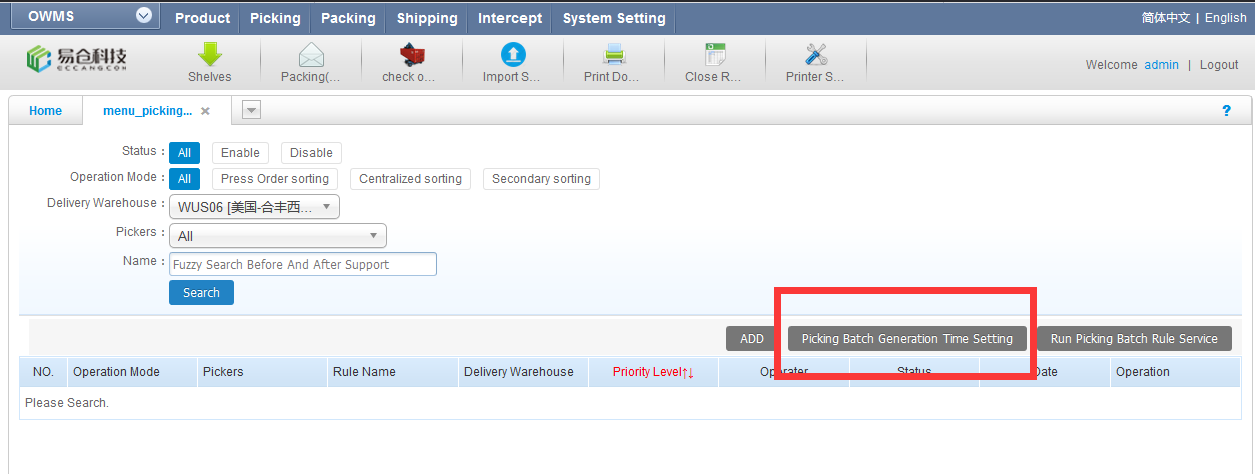

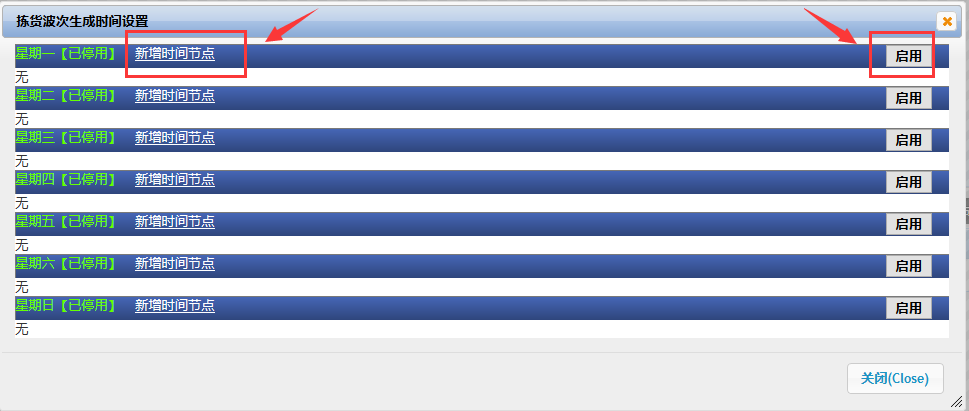

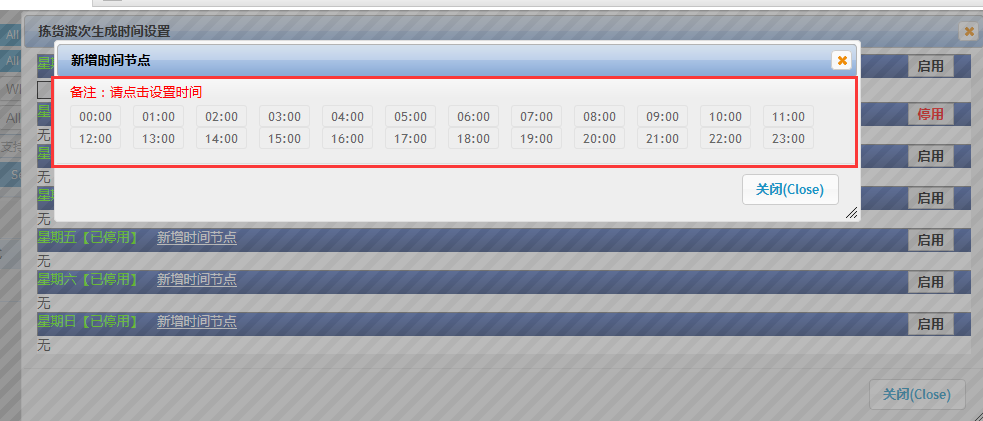

4、set creating time

After picking rule has been set, need set the time to create picking list,multi-select the day and time, than active the rule.

...

3、it can also submit run by artificial, when large amount of order in the ERP.

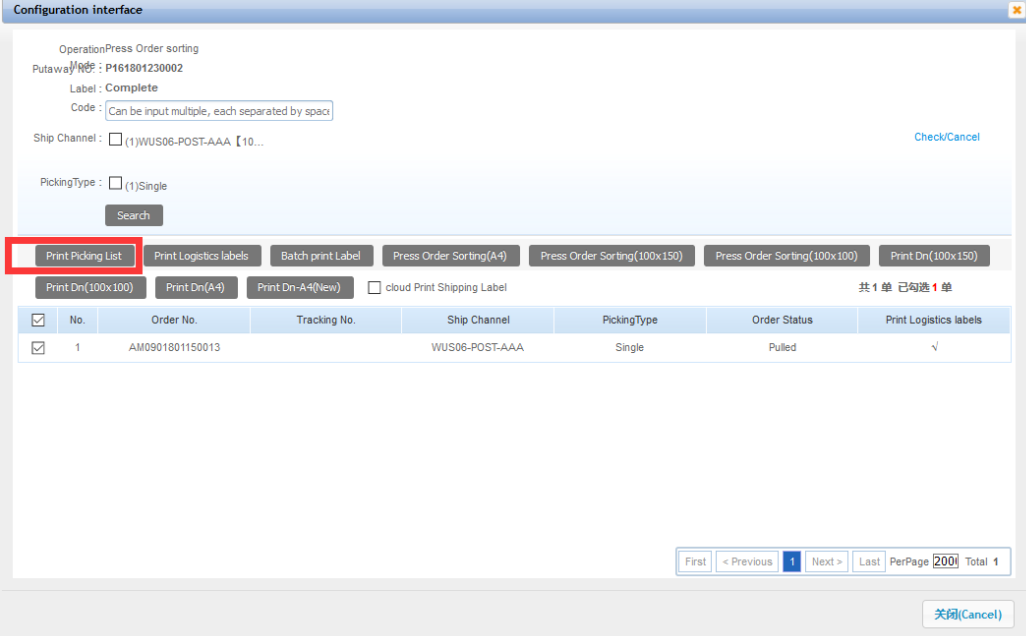

5、How to print the picking list

1、Create rule is【manual】,print in【picking——>manual picking task 】

...

3、all picking list can been find in shelves list

二. How to shipping out order

1. Shelves the order

According to order(single order、one SKU more than one QTY、multi-order)、carrier、service、warehouse area .etc.

...

The order which cannot match the auto picking list create rule still need create the picking list by manual.

2. Shelves list

1、select the list to bind picker

...

2、click the Distribution, print the picking list

三、Packet

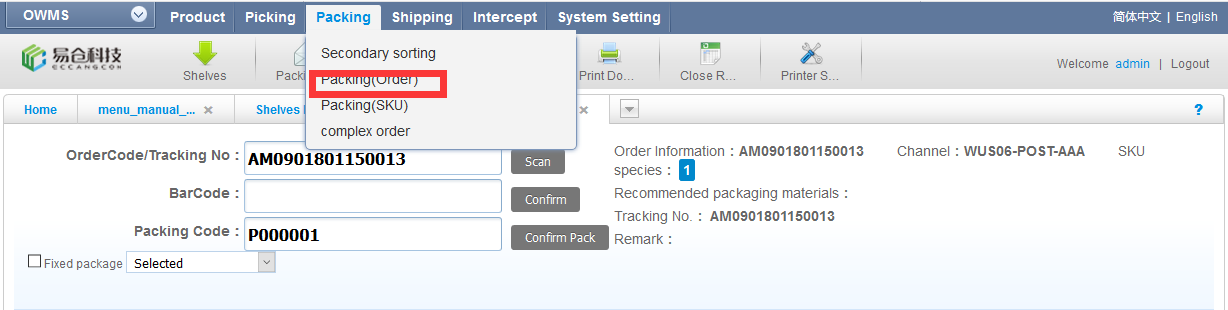

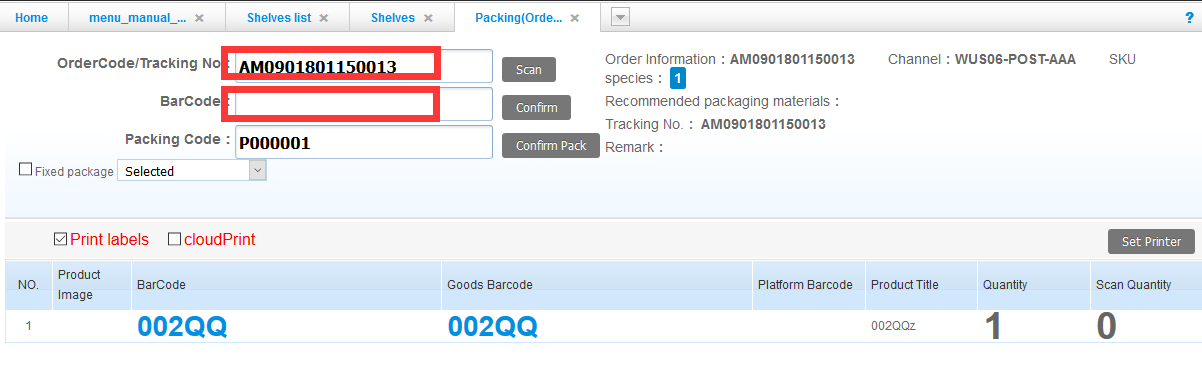

1、Packing(order)

If select operation mode is Press Order Sorting, use Packing order.

Scan the order barcode, then confirm the SKU, if the SKU is right it will print the shipping label after confirm automatically.

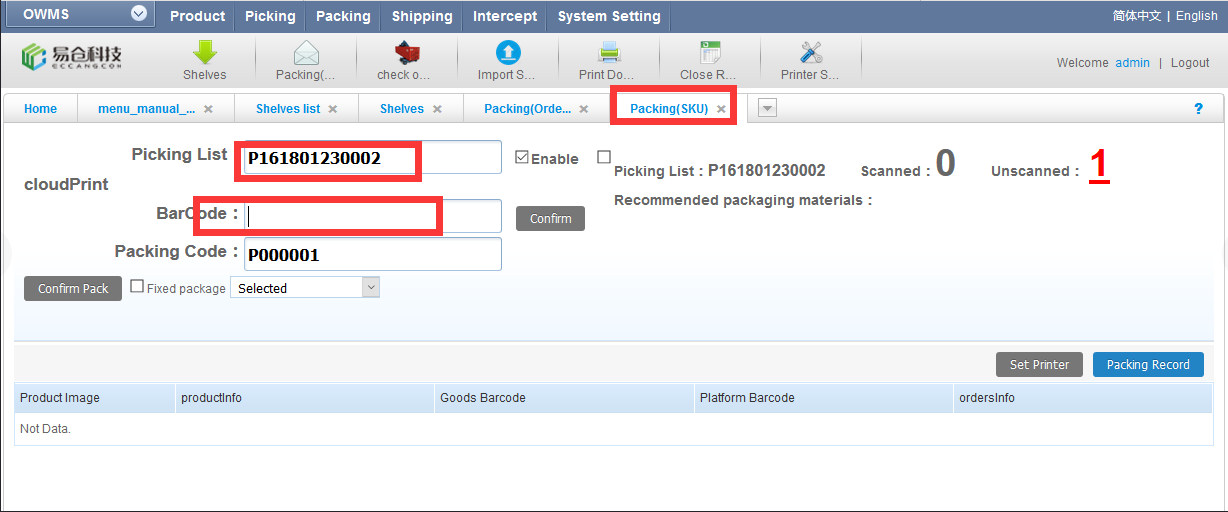

2. Packing(SKU)

If select operation mode is Centralized Sorting, use Packing order.

Scan the picking list barcode,confirm SKU,if the SKU is right it will print the shipping label after confirm automatically.

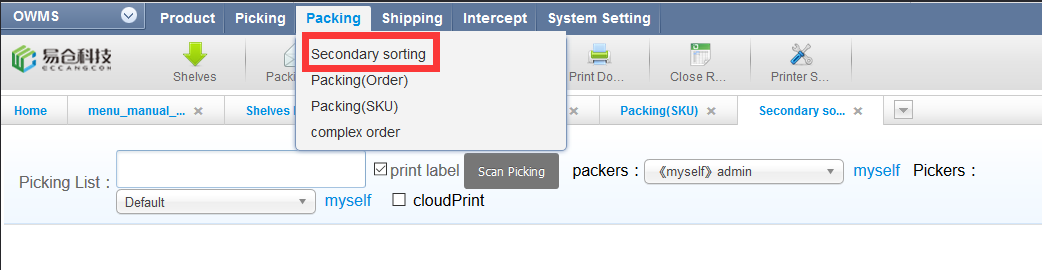

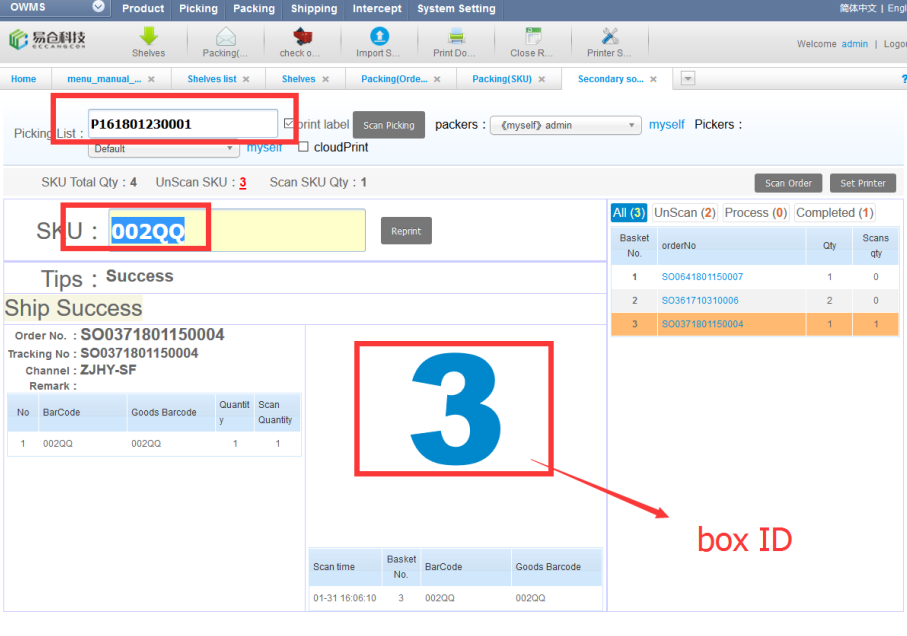

3. Secondary sorting

Scan the picking list barcode. scan the SKU, it will show the box ID, put the item in the box. One box per order, if the box of item is complete, it will print the shipping label.

4. order check out

After order pack, check out the order. Weight the order and put the order to different carrier bag.

...